From dairy and meat to confectionery and fruit, the food processing industry is thriving and demand continues to grow. Among the many gears, pumps, conveyors, mixers and motors that help keep the production lines moving, lubricants are playing a vital role.

Food-grade lubricants not only need the qualities of conventional formulations, such as protecting against corrosion, reducing friction and wear, and withstanding diverse temperature ranges, but they must also boast very specific attributes suited to these extremely demanding and highly regulated environments.

Operators are seeking solutions that protect equipment and cater for potential water contact, dust, bacteria or fungal growth, as well as possible contamination. Equally important is ensuring the lubes, greases and oils are safe should they come into contact with food.

Given their prevalence, food-grade lubricants are always under scrutiny.

Concerns continue to linger about mineral oil saturated hydrocarbons and mineral oil aromatic hydrocarbons and their effects on public health, with the European Union calling for stronger controls. This past year, France also opted to ban the use of titanium dioxide as an additive in foods. TiO2, also referred to as E171, is commonly used as a whitening agent. There is speculation it could potentially penetrate the protective walls of human organs and cause health problems if consumed. Since January 1, it has been prohibited for food use throughout the country.

It is now two decades since NSF International, an independent, third-party organization, was handed the baton by the U.S. Department of Agriculture to monitor and evaluate food-grade lubricants. Its H1 registration mark is by far the most commonly used and recognized category worldwide. H1 lubricants are meant for use in machinery where incidental food contact may occur—not in direct contact with food.

|

“In terms of chemicals used in food processing and food handling facilities, the requirements for lubricants are some of the most stringent.”

— Orsi Dezsi, NSF

|

Other categories, such as H2, stipulate there should be no food contact at all and tends to cover lubes used in equipment such as enclosed motors. H3, meanwhile, refers to edible or soluble oils typically used to protect components from rust, for example, and are safe for food contact surfaces.

“In terms of chemicals used in food processing and food handling facilities, the requirements for lubricants are some of the most stringent,” according to Orsi Dezsi, business unit manager for nonfood compounds & food contact material services with NSF. “We look at what is acceptable for incidental food contact use, and want to make sure the minimum amount is used to safely accomplish the technical effect on the equipment.”

NSF carries out over 227,000 food safety audits annually and closely collaborates with regulatory agencies such as the U.S. Food and Drug Administration and USDA. Some 45% of the products across its 70 category codes are food-grade lubricants, noted Dezsi, with over 11,000 currently registered.

“H1 registration is a voluntary standard, but most food manufacturers now use it almost as a requirement, as they seek assurance that these chemical compounds have been looked at and are safe,” she said.

H1 has established itself as the global guideline for lubricants and compounds, she added. Over 60% of the manufacturers currently registered with NSF are outside the United States.

“This is an industry that is constantly innovating and looking for new ingredients to either boost the performance of those products or improve them from a sustainability perspective. We’re seeing a lot of lubricant manufacturers looking for new substances and chemistries. H1 is so well recognized that many now use it as the baseline in how they formulate their products.”

An approved product can bear the NSF mark and is listed in its online directory (www.nsfwhitebook.org), which is updated daily. Formulators are required to declare their lubricant’s ingredients, including any proprietary mixtures, as well as submit the relevant literature and labeling for review. Separate testing is not typically required.

The newer ISO 21469 standard, meanwhile, is more rigorous than NSF H1 and raises the bar even higher. First introduced in 2005, this has set the benchmark for food-grade lubricants, requiring mandatory testing and an annual audit. It assesses the formulation, manufacture, use and handling of the lubricant.

While H1 is focused on the food industry, ISO 21469 has a broader industry scope and covers animal feed, cosmetics and pharmaceuticals as well.

“We’re finding that more and more lubricant manufacturers want to differentiate themselves with the ISO certification,” said Dezsi. “Awareness about public health and the importance of food safety is increasing, and if that continues, we’ll definitely see more requests for H1 registrations and ISO 21469 certification in the future.”

Anne-Margreet van Huffelen, marketing and communications manager with Anderol, said there is now a far better understanding of the benefits of food-grade lubricants.

“This is becoming a more important market as, in many countries, the control policies in food processing plants are sharpened and there is increased awareness of the importance of food grade lubricants,” she said.

“These products are really high quality and are not the same as general lubricants like hydraulic or slideway oils,” added Cagri Canga, industrial sales manager at Total Lubricants. “Food-grade lubricants are very specialist and affect everything from the machinery through to the packaging.”

“These lubricants can have a direct effect on people’s health so customers seem to be less interested in price and more concerned about performance, and that all the regulations are being met,” he added. “They want to understand exactly what is inside the additives from the [health, safety and environmental] point of view and demand approvals are NSF H1. It’s important that we’re transparent with our customers.”

For that reason, Canga said more suppliers are sharing technical data, including material safety data sheets and technical data sheets, as well as offering value added services such as digital monitoring tools that help track performance, productivity and efficiency. This is an area that Total has found is quickly gaining traction.

Lubricants suppliers are always looking to strengthen and improve their portfolios, products and services. With the food industry flourishing and users reliant on machinery that runs as safely and effectively as possible, focusing on food-grade lubricants could be a recipe for success.

In this Spotlight, Anderol discusses its development of high-performance food-grade lubes.

High-performance Food-grade Compressor Oils at Competitive Prices

Anderol® Specialty Lubricants, the finished fluid division owned by LANXESS, has formulated a unique, high-quality food-grade semi-synthetic compressor oil that offers outstanding performance at a competitive price.

Semi-synthetic food grade oils are formulated from synergistic blends of severely hydrotreated, hydrocracked (Group III) base oils to provide a more refined, high-quality product. These are enhanced with premium synthetic esters and proven additive technology, which help to improve viscosity, wear resistance at higher temperatures, and stress levels. Furthermore, this also increases their detergency properties, resulting in clean machinery lubrication.

Anderol®’s FG S Series offers some of the most desirable characteristics of a premium, fully synthetic lubricant at a significantly lower price. This makes it the ideal choice for customers looking to take advantage of the benefits afforded from synthetic oils over mineral oils without increasing costs. Compatibility is assured with Anderol® S-Series lubricant and there is no need for special precautions when switching from a mineral oil-based lubricant for use with paints, seals, gaskets and hoses.

Successful field trials have shown the oil life of ISO VG 46 and ISO VG 68 exceeds 6,000 hours and can be as high as 10,000 hours.

The FG S Series has numerous advantages over mineral oils, including:

- Lower cost (total cost of ownership)

- Energy savings of up to 4%

- Synthetic grade protection for expensive equipment

- Superb deposit and sludge control

- Cleaner machinery conditions

- Excellent thermal and oxidative stability

- Superb lubrication and cooling properties

- Excellent heat transfer properties

- High stability even in extreme conditions

- High-temperature shear stability

- Low volatility for longer life

- Good demulsibility and foaming resistance

- Excellent high/low temperature performance

- Elimination of seasonal oil changes

- Cooler compressors

- Extended drain intervals

- Extended lifetime (an additional 2,000 hours)

Anderol®’s FG S range excels in testing compared with standard mineral oil.

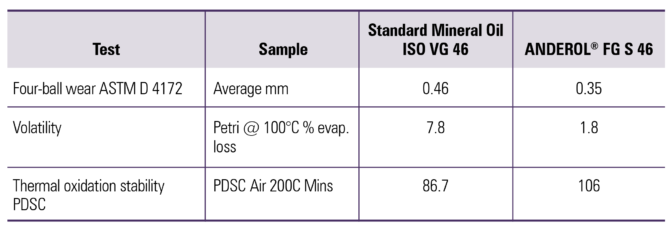

In four-ball wear tests used to evaluate the anti-wear properties of a lubricant, the Anderol® FG S 46 outperforms standard mineral oil.

The scar diameter left as a result of the test determines the ability of the lubricant to prevent wear. The smaller the scar diameter, the better the protection.

Although a four-ball wear test result of less than 0.5 mm is generally regarded as very good, tests indicate that the Anderol® FG S 46 lubricant has a result of 0.35 mm—demonstrating a very high film strength.

The volatility of a lubricant defines its evaporative loss characteristics. The more volatile it is, the lower the temperature at which smaller hydrocarbon molecules will be driven off or evaporated. The loss of smaller hydrocarbons from the oil can increase the viscosity, especially at higher temperature application. A more volatile lubricant also means greater flammability. The oil film could break on the cylinder, resulting in wear as well as increased oil consumption.

Tests show that the percentage evaporation loss at 100°C over 22 hours is only 1.8% for Anderol® FG S 46 compared with 7.8% for standard mineral oil.

The thermal oxidation stability PDSC test shows equally impressive results. High-pressure differential scanning calorimetry is a thermal analytical method that allows for a fast and reliable determination of the thermal oxidation stability of the lubricant. The PDSC curve is used to determine the beginning of oxidative degradation. The time from the first exposure to air or oxygen until the onset of the oxidation is called the oxidation induction time. The longer it takes until oxidation occurs, the better the quality of the product.

Under test conditions of 1-4 mg, 200°C, heat rate 100°C/min., 500 psi oxygen, the Anderol® FG S 46 clearly offers much better oxidation stability (106) versus standard mineral oil (87).

Just as the service life of the lubricant is important, so too is its deposit control.

Anderol® FG S 46 boasts exceptional deposit and sludge control, as well as an extremely low degree of deposit formation versus other products.

A series of petri scale tests were completed to demonstrate its performance and thermal oxidation stability. (Visit https://anderol.com/news/fg-s-series for the full results.)

All sample products were placed in a petri dish, heated to 220°C and monitored.

After eight hours, Anderol® FG S 46 was lighter in color than its competitors, indicating its thermal stability. It also displayed no sign of sediment.

Even four hours later, its color was largely unchanged while the others had darkened considerably. After 12 hours, it still did not show any polymer/deposit formation.

The Anderol® FG S series proves that not only can food-grade lubricants provide excellent levels of performance, but that it can be achieved with lower maintenance costs and minimal oil waste. Optimal lubrication without compromise. Σ

To find out more, visit anderol.com

Anderol® is a trademark of LANXESS Deutschland GmbH or its affiliates. Registered in many countries in the world.