Managing metalworking fluids in a safe, efficient and cost-effective way can be a daunting task. To ease the burden a bit, the United Kingdom Lubricants Association teamed up with Great Britain’s Health & Safety Executive and the University of Sheffield’s Advanced Manufacturing Research Center to create a series of videos designed to help workshop owners and machine operators best manage their metalworking fluids. The video series—titled Looking After Your Metalworking Fluids—consists of ten modules on various metalworking fluid-related topics.

Health and Safety

It is no secret that metalworking fluids can be harmful to human health when they are not handled properly. What exactly is it about these fluids that can be so harmful?

According to UKLA’s video series, many different types of bacteria can develop in metalworking fluid. These include pseudomonas oleovorans, pseudomonas aeruginosa and achromobacter sp.

What’s more, during use, water-mixed metalworking fluids can be contaminated with hazardous chemicals and metals. Because of this, “it is important to look after the cutting fluid,” said Gary Barnsley, senior machinist with the University of Sheffield. “It’s better for us if it’s maintained. We can catch [contact] dermatitis if not.” Contact dermatitis is a skin rash caused by contact with certain irritating substances.

The seriousness of this is not slight. UKLA stated that an engineering company was sentenced and fined in May 2021 after an employee developed an allergic form of dermatitis when their skin came into contact with metalworking fluid. After the diagnosis was made, it was concluded that the employee could no longer continue working with metalworking fluid, as the risk to health was too severe.

The risk does not stop at dermatitis, either. Small particles can be inhaled during operation. Coughing, chest infections, breathing difficulty and weight loss may be indicators that an operator is developing a serious lung disease because of metalworking fluid inhalation.

“The key risks of metalworking fluids are dermatitis—skin infections and skin problems—and also lung diseases as well from the misting or any bacteria that might be in the misting getting in your lungs,” said Caroline Slinn, one of UKLA’s metalworking fluid suppliers.

According to the Centers for Disease Control and Prevention, other respiratory conditions that can result from metalworking fluid inhalation are occupational asthma, chronic bronchitis and hypersensitivity pneumonitis.

Because of the health and safety risks associated with metalworking fluids, certain precautions must be taken prior to operation. For instance, when taking samples for testing, proper equipment should be worn. This includes single-use gloves, eye protection and other protective clothing, such as face masks.

Visual and Odor Checks

Visual and odor checks should be completed routinely (i.e., daily) to check for deterioration of the quality of the fluid. What are some of the major red flags for which inspectors should be looking?

First, changes in color or clarity may be a sign of fluid deterioration.

Similarly, inspectors should keep an eye out for slime and deposits on the surfaces of the sump and the filters. “You can get big layers of biofilm, which is sort of a slimy substance that lies on top of the metalworking fluid,” said Fiona McGarry, an HM inspector of health and safety. “If left untreated, that can just build up and up, and it’s just really grungy. The air can sort of become contaminated around there, and you get a misting on all the surfaces around the machine as well.”

UKLA suggests looking for signs of tramp oil (any visible oil, usually dark in color, that can contaminate a metalworking fluid supply). Other common warnings that a fluid needs maintenance is foaming in the sump as well as signs of creaming or metal fines and swarf.

Foaming in the sump.

© Image courtesy of United Kingdom Lubricants Association

Odor can be a tell-tale sign of degraded fluid, too. Any sort of rancid smell or one resembling rotten eggs indicates a problem with the fluid. This odor can be caused by the growth of bacteria and is made worse when metalworking fluid has been left stagnate for a period of time and has not been properly circulated.

Finally, it is important to check for blockages that may affect the flow of coolants.

When all these checks have been completed, observations should be recorded on a fluid maintenance record chart.

Sampling Fluid

Visual and odor checks are a quick and easy way to determine if a metalworking fluid needs to be treated in some way, but they are more or less preliminary checks that must be accompanied by more formal testing of fluid samples. This is necessary because fluids can be contaminated with bacteria that may not be immediately apparent.

What kinds of samples are necessary, and where can they be found?

According to UKLA’s video modules, it is essential to obtain a representative, well-mixed sample of the fluid that is free from machine oil and other contaminants, which could cause bias of test results. Ideally, the samples should be taken from inside the machine in which they are operating at the coolant delivery point. Samples can also be taken from a sampling tap that is fitted to a central point in the supply line of the fluid.

In cases where the fluid cannot be taken from these two locations, samples can be drawn from the sump. However, when doing so, the surface of the fluid should be disturbed and the sample should be taken from the fluid below the surface. This ensures that an excess of contamination and debris are not captured along with the fluid sample.

Of course, sampling should not occur near dangerous moving parts. The person collecting the samples should also be aware of other hazards, such as sharp metal swarf.

Testing for Quality

What fluid characteristics must be tested to inform machine operators of fluid quality?

First, UKLA suggests testing for tramp oil concentration. This is a vital practice for a few reasons: Tramp oil is likely to encourage the growth of bacteria, and it also affects the emulsion stability of metalworking fluids, which can increase the presence of mist as well as smoke. UKLA recommends that tramp oil concentration be checked at least weekly. How is this done?

A sample of fluid is transferred into a measuring cylinder and allowed to stand for 24 hours. During this time, the tramp oil will separate from the emulsion. The tramp oil concentration is then measured and should make up less than 2% of the total fluid volume.

Excess tramp oil can be removed mechanically using belt and disk skimmers, oil-water coalescers or wet vacuum suction equipment.

Another important test is one to measure the concentration of metalworking fluid, as most fluids are concentrated and must be diluted before use. Over time, the concentration of fluid can change due to the evaporation of water. This affects the quality of lubrication and could cause some metal parts to corrode. It may also promote the growth of bacteria.

It is important to use clean, high-quality water in fluid dilution to maintain fluid quality. Water quality should be tested for pH, hardness and bacteria before being mixed with metalworking fluid. Water quality requirements are generally outlined by the fluid supplier.

“If you think about it, water is the main thing that’s going into your machine,” Slinn said. “It could be 90%-95% of what you’re machining with, so it needs to be good quality to start off with.”

Mixing of fluid and water is the most critical step. “It is important to keep the right concentration level because if the levels go high or low it affects the way the machine runs, and it’s also beneficial to us to have it at the right consistency,” Barnsley said.

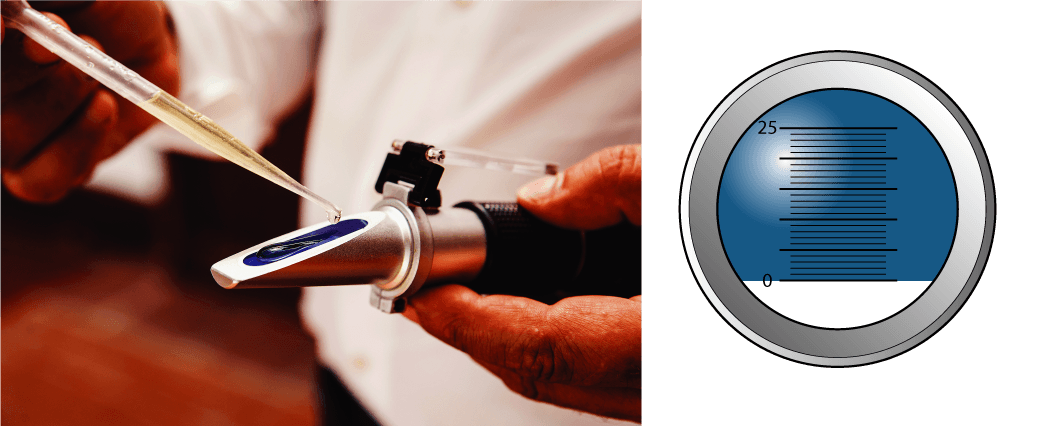

Once the metalworking fluid is mixed and circulating through the machine, UKLA recommends checking the concentration weekly. This can be done by using a refractometer, which is a handheld optical instrument used to estimate the mixed concentration of soluble metalworking fluids by measuring the change in light passing through a fluid at different concentrations. The accuracy of these measurements can be affected by the temperature of the instrument, so it should be stored in its case and allowed to warm or cool to room temperature. It should be cleaned before each use with clean, cold water and a clean tissue or cloth.

Using a Refractometer to Test Metalworking Fluid Concentration

Calibrated refractometer reading 0 with water

The tool must also be calibrated before use. This is done by placing several drops of clean water between the plastic cover and the prism. Then the user should hold the instrument horizontally to their eye and point it toward a source of light (e.g., a window or an artificial light source). The user can then look into the eye piece and use the calibrating knob to ensure that the boundary line is at zero in the viewer. The plastic cover can then be lifted and the prism dried with a clean cloth.

To test the metalworking fluid, place one or two drops of fluid on the prism and close the plastic cover. The reading is not a direct measure of concentration. Instead, each fluid has its own refractometer correction factor, which can be found on the product information sheet provided by the fluid supplier. The concentration can be calculated by multiplying the scale reading by the adjustment factor relevant to the particular metalworking fluid being used.

It is important to take prompt action when these test results show that the fluid concentration is outside the bounds set by the fluid supplier. “Looking after the concentration is one of the most important factors because you’re using the ingredients of that product at its optimum level,” said UKLA metalworking fluid supplier Ian Harris. “If the product concentration is too low, the additives are too dilute to be effective. If they’re over concentration, you don’t really get any extra benefits, just extra costs.”

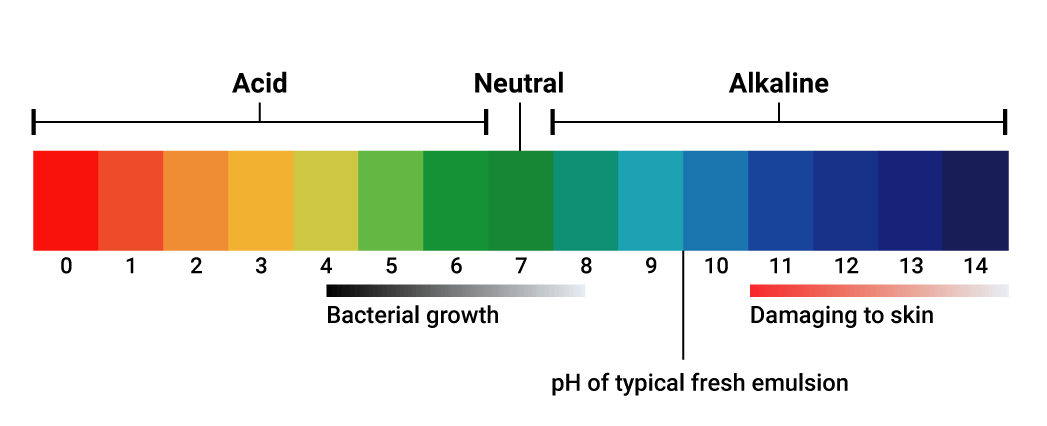

Other important tests that should be performed routinely are those for fluid pH and bacterial growth.

Measuring the pH of Metalworking Fluid

For more information on how to manage metalworking fluids in a safe and effective way, be sure to check out all ten of UKLA’s video modules on its YouTube channel at https://www.youtube.com/@UKLAMetalworkingFluidGroup/videos

Sydney Moore is managing editor of Lubes’n’Greases magazine. Contact her at Sydney@LubesnGreases.com