As individuals, companies and governments around the globe become increasingly focused on sustainability, clean energy sources are becoming ever more important. In fact, 16 countries generated a total of about 3.6 billion kilowatt hours of wind electricity in 1990, according to the U.S. Energy Information Administration. In 2020, 129 countries generated about 1,597 billion kWh of wind electricity.

While wind turbines are expected to be key players in achieving a truly sustainable future, they do come with a few major tribological challenges—including micropitting, white etching cracks, dents, scuffing, fretting corrosion and more—that can affect both the cost of energy and the availability of it.

So how can lubricants—particularly greases—help to overcome these challenges and increase the reliability of these important energy-generating machines?

Types of Lubricants Required

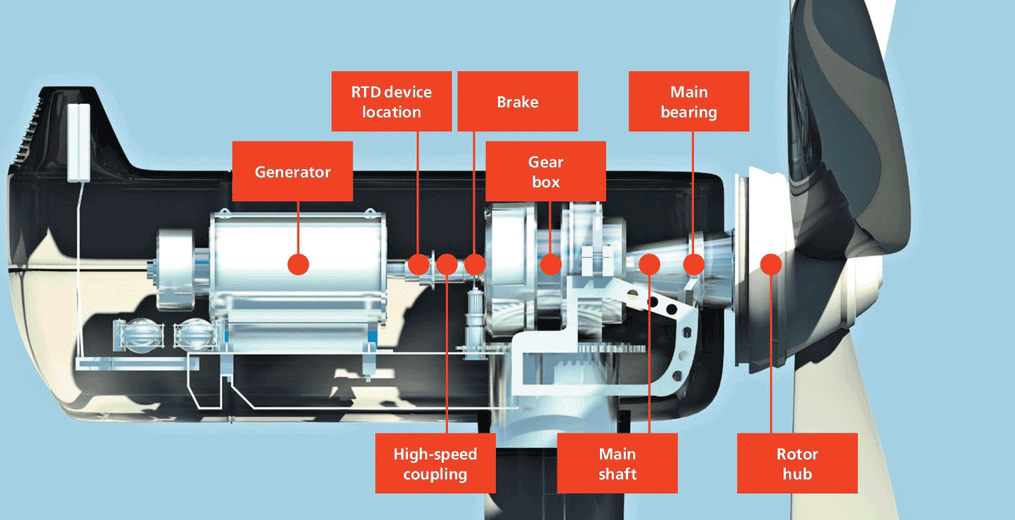

Wind turbines are made up of several different types of bearings, a gearbox, a generator and several other critical parts that must move together to generate electricity. (See Figure 1 for an illustration of a wind turbine’s major components.) In order for all of these components to work effectively, high-quality lubricants are required. For instance, yaw drive bearings, pitch bearings, main shaft bearings and generator bearings all require greases to accommodate smooth operation, while gearboxes require an oil lubricant.

F Is for Failure

Several things can go wrong in a wind turbine. What are those things, and how can they be remedied?

In a webinar hosted by Auburn University, Harpal Singh, senior staff, tribology and materials failure analysis for Rivian Automotive, listed a few common types of failure in wind turbines and suggested some potential solutions:

- False brinelling and fretting corrosion generally cause damage to pitch and yaw bearings and occur under small, repetitive oscillations with or without corrosion. In this type of failure, the lubricant (i.e. grease) is essentially squeezed out of the bearing, and the oxidation layer is worn away. The absence of the oxidation layer leads to metal-on-metal contact, which in turn leads to corrosion.

One way to prevent false brinelling and fretting corrosion is to periodically check that contacts are adequately lubricated. The grease selected for this application should include antiwear additives. Bearings can also be lubricated with solid lubricants or coatings and surface treatments.

- Micropitting mainly affects the main shaft bearing and occurs when asperity shear, plastic deformation or surface asperities cause micrometer-sized pits to form. The micropits then remove materials in contact with each other, altering the surface profile and creating stress concentrations. Factors affecting micropitting include surface finish, lubricant, load, temperature and speed, among others.

A viable way to avoid micropitting is by the use of hard (diamond-like carbon) or sacrificial (black oxide) coatings. Coatings may help to manage surface roughness. Greases formulated with specialty additives (i.e. nanoparticles) may also help to prevent micropitting.

- Dents and indentations affect several mechanical components and are generally caused by foreign, abrasive particles that become trapped between rolling elements and raceways. The severity of damage caused by dents depends on the dents’ diameter in proportion to the contact width.

Because possible sources of abrasive particles include wear particles generated during run-in and contamination during manufacturing or maintenance activities, one solution can occur at the manufacturing stage; using certain diamond-like carbon coatings on rolling elements can prevent wear and the generation of debris before it becomes an issue. Also, running the oil through appropriate filters can rid lubricant of debris.

- Scuffing or smearing is a type of adhesive wear that occurs in two mating surfaces when material transfers from one surface to another under frictional heating. This type of failure affects high-speed shaft bearings and occurs under high load and slip conditions.

Selecting the correct lubricant can help to manage scuffing or smearing.

- White etching cracks are responsible for approximately 60% of all wind turbine high-speed bearing failures, according to a whitepaper published by ExxonMobil. While the exact cause of white etching cracks is still being explored, hydrogen ingress, stray currents, transient loads and frictional heat energy are thought to be possible culprits.

Solutions for white etching are still being investigated. Research conducted by ExxonMobil suggests that selecting the correct gear oil may help. Oils formulated with ZDDP (zinc dialkyldithiophosphate), which is a common antiwear additive, tended to lead to white etching cracking during ExxonMobil’s testing. White etching cracks were also observed in instances where oils containing a combination of sodium and calcium alkyl sulfonates were used. White etching cracking was observed for oils blended with calcium, magnesium or sodium alkyl sulfonates only when those additives were included in increased concentrations.

So which formulations did help to prevent white etching cracking? According to ExxonMobil, no failures were recorded for oils formulated with zinc dialkyldithiocarbamate as well as ashless antiwear additives and non-metallic additives.

Trends Affecting Lubricant Formulations

Today’s wind turbine designs are more sophisticated than they once were. Because of this evolution in engineering, wind turbine lubricants have also had to evolve to keep pace. So what characteristics must a modern wind turbine lubricant possess, and how have trends in today’s wind energy industry impacted formulations?

Materials Compatibility. Material-lubricant compatibility is front of mind for lubricant and grease manufacturers. The lubricants used in today’s wind turbines must not interact negatively with the various metals of bearings and gears as well as the materials used in seals and other components. For instance, some polyalkalene glycol-based lubricants can interact poorly with coatings and seals.

Wind Turbine Design. Evolution in wind turbine design has also driven innovation for lubricants. Today’s wind turbines have been engineered to be significantly larger than their predecessors in order to increase the efficiency of power generation. Furthermore, wind turbine manufacturers have aimed to decrease weight by downsizing gearboxes and consequently lowering sump volumes. Larger loads in conjunction with smaller sumps place increased stress on the lubricants, and today’s lubricants are expected to step up to the plate.

Remote Locations and Extreme Temperatures. While bearings and gearboxes in wind turbines are designed to have a lifespan of about 20 years, additional failures can and do occur due to challenging operating conditions.

Notably, wind turbines are located in some of the most remote locations in the world. Because of this, their components as well as the lubricants that keep them running as they were intended must withstand some of the most extreme conditions on earth.

According to the International Energy Agency’s Wind TCP Task 19, as of 2015, a quarter of the world’s wind turbines were installed in very cold climates, and that portion was set to increase through 2024. This statistic demonstrates a need for lubricants that can maintain their fluidity when the temperature is consistently below freezing.

A significant portion of wind turbines are also installed in off-shore locations. An off-shore environment requires lubricants that can withstand wet and salty conditions. In these instances, water ingress as well as rust formation are significant factors that must be overcome. According to a Machinery Lubrication article, the SKF Emcor rust test is being evaluated to include testing with salt water.

Additionally, the remote locations of some wind farms require lubricants that are longer-lasting. After all, performing maintenance on wind turbines that are not located in easily accessible areas is both difficult and expensive.

Base Stock Performance. Perhaps the most important formulation consideration is the type of base stock selected, as the base stock makes up the majority of most finished lubricants. As is the case with many other types of lubricants, many manufacturers of wind turbine greases and gear oils are touting synthetic base stocks as the superior option. ExxonMobil boasts metallocene polyalphaolefins as the most suitable option to date because greases formulated with these Group IV base stocks tend to exhibit superior low-temperature performance, making them especially suitable for installations in cold climates.

Furthermore, mPAOs generally offer enhanced shear stability and high viscosity index as well as suitable foam and air release performance compared to their conventional mineral oil counterparts. According to Kluber Lubrication, a high viscosity index makes for easier start-up at low temperatures, reduces power loss and ensures the formation of a load-carrying lubricant film at high temperatures.

Other manufacturers have experimented with PAGs and esters, as they are believed to offer resistance to certain failures, like micropitting. However, as mentioned above, PAGs are often accompanied by compatibility issues with coatings and seals. Also, certain combinations of base stocks (for instance, esters and polyalphaolefins) are not generally used in wind turbine lubricants because of significant hydrolysis issues.

Additive Chemistry. Demand for lubricant additives is mostly made up of chemistries that are already well established in the market. These include the slate of traditional antiwear, extreme pressure and antioxidant additives, among others.

However, that doesn’t mean that additive companies are resting on their laurels. Instead, they are diligently looking into more novel additive technologies, such as nanoparticle additives, which are currently on the more experimental side and may not be very cost effective for many wind turbine operators. Fortunately, some industry insiders believe that price parity may not be too far away.

Nanoparticle additives differ from traditional additive chemicals in that the tribofilm formation process is different. Simply stated, nanoparticle additives can boost a finished lubricant’s surface protection.

A Good Grease?

Manufacturers formulate their greases based on a set of necessary performance characteristics. These include but certainly are not limited to load bearing capability, shear stability, low-temperature flow, corrosion control and film thickness.

In order to achieve these performance traits, formulators must carefully select the thickener type, the base stock, the additives and more.

The consistency of the final grease product is also vital.

So when all is said and done, what makes for an effective wind turbine grease formulation?

Unfortunately, that answer is far from simple. Different wind turbine bearings and gears operating in different conditions and undergoing varying frequencies of maintenance require very nuanced formulations. While there are undoubtedly some common traits that these greases must possess, the bottom line is that the grease needs to thrive in the particular application.

Additionally, it is important for wind turbine grease formulations to conform to certain industry and OEM specifications by passing laboratory tests as well as proving their performance in field trials.

Sydney Moore is managing editor of Lubes’n’Greases magazine. Contact her at Sydney@LubesnGreases.com