The market for magnetorheological fluids has witnessed significant development and growth since these “smart” fluids were discovered more than 70 years ago. Their usage has increased in varied applications, but like many newer technologies, some practical challenges still exist. Research indicates that using MR fluids alongside lubricating greases may help repel some of these negative forces.

Discovered by Jacob Rabinow in 1948 at the United States National Bureau of Standards (now the National Institute of Standards and Technology), MR fluids change their rheological behavior drastically—and reversibly—upon application of a magnetic field, said V.K. Sukhwani, a professor in the Department of Mechanical Engineering at Ujjain Engineering College in the central Indian state of Madhya Pradesh.

The change can be quite dramatic, with the fluids morphing instantaneously from a low-viscosity liquid to a high-viscosity semi-solid or even a solid state when exposed to a magnetic field, which is created by an electromagnet that can be switched on and off.

“The viscosity change is rapid and completely reversible and can be used to bring controllability in operation in engineering applications, i.e. dynamic change in performance measures like damping resistance in dampers and braking torque in brakes,” Sukhwani said at the annual meeting of the Indian chapter of the National Lubricating Grease Institute in February, held in Indore, Madhya Pradesh.

Given their advantages, MR fluids are increasingly being used in a wide range of applications such as automotive, robotics, aerospace, military and defense, building and construction as well as electronics and medical applications.

For example, Japan’s Akebono Brake Industry Co. aims to debut its MR Fluid Brake this year, according to its website. In the brake, MR fluid fills a gap between a rotating disc and a fixed disc. When a magnetic field is applied, the fluid changes to a semi-solid, and the shear resistance against the rotating disc acts as the braking force. The brake produces no dust, sound or vibration, and is particularly suited to automated driving technologies because of its responsiveness, the company states.

In automotive suspension systems, such as Parker Lord’s systems made for some Audi, Buick, Ferrari and Holden models, “controllable MR fluid replaces traditional hydraulic fluid in each shock absorber. As sensors monitor road and vehicle conditions, a controller modifies the damping characteristics up to one thousand times per second,” the company’s website explains. “This enables dramatic improvements in both ride comfort and handling.” The systems boast fewer moving parts, low power consumption and quieter operation, among other advantages over traditional suspensions.

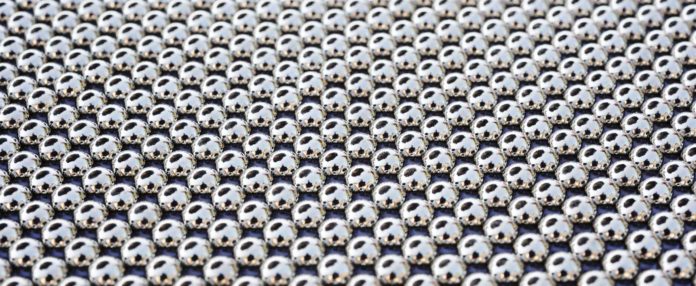

A typical MR fluid consists of 20 to 40 percent by volume pure soft iron particles, typically 1 to 10 microns in size, suspended in a non-magnetic carrier liquid such as mineral oil, synthetic oil, water or glycol. A variety of additives, similar to those used in commercial lubricants, are added to prevent sedimentation, promote particle suspension, enhance lubricity, modify viscosity and prevent wear.

The magnetic material, usually iron, should have the lowest possible coercivity, or resistance to changes in magnetization, and highest possible saturation, or the point at which the material cannot be further magnetized, Sukhwani said. The magnetic materials that can be used are carbonyl iron (high-purity iron powder derived from decomposition of iron pentacarbonyl), iron-cobalt alloys, and manganese-zinc ferrite and nickel zinc ferrite powders.

Explaining the basic characteristics of MR fluids, Sukhwani said that in their “off state,” i.e. in the absence of a magnetic field, these fluids behave like Newtonian fluids and have low apparent viscosity. Newtonian fluids have constant viscosity that is independent of stress. But in the “on state,” or under the influence of a magnetic field, the fluids show non-Newtonian behavior—meaning the viscosity changes under stress—and particles polarize to form a chain or columnar structure parallel to the applied field. This increases the apparent viscosity of the fluid and develops yield stress, which is known as magnetorheological effect, he added.

Sukhwani said the MR technology has good potential for various engineering applications demanding controllability in operation, but there are some problems associated with the fluids. In addition to a high cost of approximately $500 to $600 per liter, they suffer from the problems of sedimentation and agglomeration of magnetic particles. They also require excellent sealing to prevent leakage. MR fluids subjected to long-term dynamic use progressively thicken and eventually become an unworkable paste, he noted.

“The cost of MR fluid is the major hurdle in its commercial viability, and sedimentation is the major issue in its mechanical applications,” he told Lubes’n’Greases.

Grease to the Rescue

Highlighting the benefits of grease, Sukhwani said the ability of any viscoplastic medium—which is capable of changing viscosity—to suspend isolated particles is characterized by the gravity yield parameter, wherein a higher value means higher sedimentation stability. Generally, grease has a higher value of yield stress compared to any liquid, such as oil, and therefore grease is a better option for preventing sedimentation compared to a liquid lubricant, he said.

Sukhwani pointed out that the use of grease as a thickening agent in the composition of MR fluids offers a single solution for both sedimentation and sealing problems.

MR grease consists of a base oil, a thickening agent (grease), a compatible additive package and soft magnetic particles, which are easy to magnetize and demagnetize. Such grease has the same quality of changing consistency upon application of a magnetic field, just like MR fluids, Sukhwani said. But even better than MR fluids, “MR grease remains within the device without any aid of sealing mechanism, with very good resistance against settling of the magnetic particles,” he added.

The potential application areas of MR grease are automotive dampers, brakes and clutches, engine mounts, earthquake dampers, shock absorbers, actuator systems and even prosthetic knee dampers.

Sukhwani noted that a number of MR devices and commercial MR fluids are available in the market. A few patents have been granted for MR grease composition, but no commercial MR grease has been made available by any manufacturer in the market so far.

Putting MR Grease to the Test

To evaluate the performance of MR grease, Sukhwani conducted a study and prepared three experimental MR greases using economical electrolytic iron powder, lithium complex NLGI 2 grease, mineral oil and an additive package for anti-wear, anti-corrosion, antioxidant and lubricity properties.

Grease 1 contained iron particles coated with guar gum, which is used as a thickening agent, emulsifier and suspension stabilizer. Grease 2 and Grease 3 were prepared with different weight percentages of the same ingredients and contained iron particles without guar gum.

All three preparations were examined for their sedimentation stability, oil separation and change in consistency in response to a magnetic field. Consistency was measured using the ASTM D217 and ASTM D1403 standard test methods, while a grease penetrometer (PNR-10 Petrotest) was used to measure the NLGI grade.

For measurement of consistency, the magnetic field was varied by applying the desired electric current using a DC power supply. Tests were performed at five different currents: 0.0 ampere, 0.5 A, 1.0 A, 1.5 A and 2.0 A. The full-scale measurement using the ASTM D217 test method showed that the magnetorheological effect produced—the incremental change in consistency—was not as large as expected. Sukhwani believed this was due to the large diameter of the grease cup (75 mm), as the intensity of the magnetic field would be lower at the center of the cup where the tip of the cone penetrates.

In order to generate more magnetic field at the center of the cup, a smaller cup and cone (half-scale measurement as per ASTM D1403) was used as an alternative. Tests were repeated and the resulting values were converted to full-scale cup and cone readings.

To study sedimentation stability, the prepared greases were placed in three similar graduated cylindrical flasks and observed for their sedimentation behavior over a period of time. The pressure filtration method (IP 121) was used to determine the greases’ tendency for oil separation during storage, while the conical sieve method (ASTM D6184) was used to determine oil separation at an elevated temperature of 100 degrees Celsius.

Sukhwani said that all three MR greases remained in a stable and well-dispersed state without sedimentation for “quite a long time.” The tests showed that synthesized MR grease has better sedimentation stability than MR fluid, because as a thickening agent the grease’s yield stress is large enough to prevent particle sedimentation in the suspension. Grease 3 showed maximum sedimentation stability because it contained the highest percentage of thickener. The sedimentation stability of Grease 1 (containing guar gum-coated iron particles) was better than Grease 2, demonstrating that guar gum plays an important role in preventing sedimentation of particles.

For all three greases, oil separation during storage and at elevated temperature was reasonably low due to the low “off state” consistency of the greases. The lowest oil separation during storage, as well as at elevated temperature, was observed for Grease 3, which contained the highest percentage of thickener. Oil separation was less for Grease 1, the composition with guar gum, as compared to Grease 2, which did not have this additive.

The experiment revealed that greater variation in consistency with the magnetic field (higher magnetorheological effect) was observed for MR grease with more iron particles. Sukhwani said the MR grease also showed good sealing and prevented leakage, which is a common problem observed in devices using MR fluids.

He concluded that research related to MR grease shows that it offers a solution to the two most important problems of MR fluids: It can mitigate the sedimentation of magnetic particles and solve the leakage problem from devices. However, more research is required to optimize MR grease composition and accurately model its behavior, Sukhwani noted.