A key test for evaluating the lubricity of metal removal fluids has been retired and a new one screwed into place in January, reported Dennis Mahoney of testing equipment maker Microtap USA. The new tapping torque evaluation standard allows for greater flexibility in both testing equipment and experimental procedures.

The legacy test method, ASTM D5619, was withdrawn and replaced with ASTM D8288, “Standard Test Method for Comparison of Metalworking Fluids Using a Tapping Torque Test Machine.” The earlier method was written for Falex’s tapping torque testing machine, which the company is no longer making, and was “very prescriptive” for that machine, Mahoney said.

As a result, fluid formulators would adapt the method to suit their own needs. “A lot of tapping torque testing was done using it as a reference but didn’t fully follow the procedure,” he noted.

North American standards organization ASTM International worked with Microtap, Falex and other companies over three to four years to develop the new standard. “The D8288 standard is very versatile and allows different test machines to be used, so long as they meet the specifications. It also allows potential [test machine] purchasers to use their own particular alloys to simulate the fluid user’s production situation as closely as possible,” Mahoney told Lubes’n’Greases.

A key research & development tool, the tapping torque test is a laboratory technique to evaluate the relative performance of metal removal fluids. “It’s important to realize that it is a comparative measurement of relative lubricity,” Mahoney emphasized. “It is repeatable on a single instrument within a test series, but it is not yet verified that absolute numeric values can transfer from one type of machine to another or from one date to another. It’s always best to evaluate the items you want to compare at the same time.”

Within a particular test series, comparisons can be made between different fluids, concentrations and operating conditions. The test is applicable to all tap types, machining speeds and alloys that can be fabricated into a test piece.

While the test is not included in any specific end-user or OEM standards, “a number of MWF suppliers have incorporated tapping torque into their development or sales support process as a measure of product lubricity, along with other tests to measure corrosion protection, tramp oil rejection, foam, etc.,” Mahoney said. “We have certainly encountered situations where tapping torque results were used to qualify products.”

Test Procedure

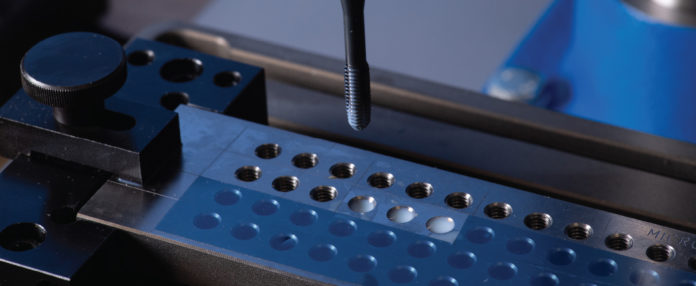

Tapping is a metal machining process to cut or form threads in a pre-drilled hole. “Unlike drilling, the axial force to push down on the tap is not required because the tap pulls itself into the part being tapped by the threads as it creates them,” Mahoney said during a webinar hosted by the Society of Tribologists and Lubrication Engineers in October.

Taps have a wide variety of geometries and coatings, but cutting and forming taps are the types used for tapping torque testing. Cutting taps remove metal during the process, and metal chips are ejected through flutes as the hole is tapped. This process requires lower torque, but if chips eject irregularly, they may cause noise or bounces in the torque.

With forming taps, no metal is removed but is instead deformed to make the threads. This process requires higher force and a metalworking fluid with higher lubricity. Form tapping provides better differentiation between fluids than cut tapping in test procedures, Mahoney observed.

The test can be performed in holes that are drilled completely through the test piece or in blind holes, which go partially into the piece. For tests using through holes, the tap is tapered at the end so that it self-centers in the hole. A bottoming tap is used for blind holes. This shape is flat at the tip so it can create threads all the way to the bottom of the hole. However, the operator must be careful that the tap is centered before beginning the operation.

In the test, precisely machined holes, created by drilling and reaming the test bar, are filled with test fluid. The bottom of through holes are taped to contain the fluid. Other versions of the test allow the fluid to be continuously dribbled or misted onto the test bar.

“The way D8288 is written with the different methods of fluid application, such as spray or immersion, is to cover people’s different techniques,” Mahoney said after the webinar. “For example, Lubrizol—which was also very helpful in test development—dribbles fluid on during the tapping process as opposed to filling a taped hole. We wanted to make certain that they could say they’re following the procedure, as well.”

Common test variables are metal characteristics, rotational speed, tap type or manufacturer and hole size, which can be undersized to create higher torque or oversized to drop the torque.

|

“The way D8288 is written with the different methods of fluid application, such as spray or immersion, is to cover people’s different techniques.”

– Dennis Mahoney, Microtap USA

|

In the D8288 procedure, all fluids are evaluated on the same test bar, with 70 to 120 holes per bar. Operators should plan for five or more holes or test runs per fluid. They should also break in new taps on three to six holes to be certain the edge of the tap is stable, Mahoney cautioned. Holes should be free of metal fines from preparation or contamination from previous test runs.

Between tests, he recommends running a control fluid or rerunning the first test fluid to be sure there is no built-up edge or other change in the tap. Built-up edge occurs when the operation generates high heat and test piece material is transferred and welded onto the tap.

Software on Microtap USA’s LT-120 tapping torque tester, which was used to develop the new standard, collects data every 1–1.5 milliseconds. Each test takes 1 second to run, and data is displayed after all tests are run. Lower torque readings indicate better fluid lubricity.

New and Improved

The D8288 standard calls for a single tap to be used for all fluids, while D5619 used separate taps for each fluid. The newer standard also includes a procedure for determining tap wear. “I think it’s a little more straightforward” than the older procedure for resolving tap differences, Mahoney said.

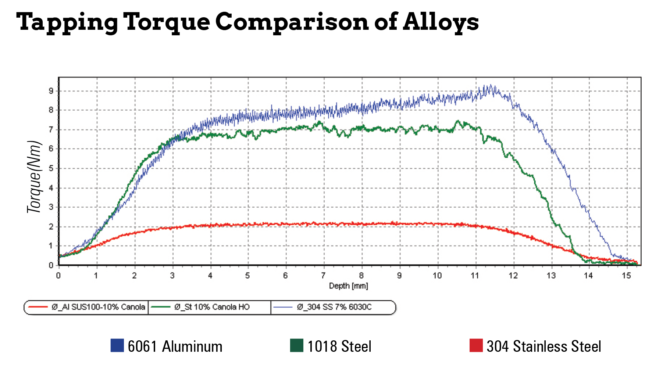

The new test uses a single test bar for up to 120 runs, as opposed to a single hole in each test piece for the older test. The LT-120 machine has a wider torque range of 0.3 to 12.0 Newton meters, compared to 0.5 to 7.0 Nm for older machines. The speed range expanded from 300–2,060 revolutions per minute to 50–2,400 rpm. Tests are typically run between 500 and 1,200 rpm, Mahoney noted.

The drive has also been changed from a stepper motor to a servo motor, enabling slower speeds and smoother operation at those low speeds. Torque readings are also unaffected by motor noise and oscillations.

And, as may be expected from a machine that is 30 years newer than its predecessor, it comes with more modern software and wider computer compatibility.

The key benefits of the new machine are higher torque and lower speeds, Mahoney highlighted. These parameters work together to allow difficult-to-tap alloys, such as Inconel, stainless steel or titanium, to be used as test bars. “As the metal becomes harder, the torque requirements are greater and the corrective action for that is to move to lower RPMs. So in the case of testing 316 stainless at 100–200 rpm, this couldn’t be done on the prior model.”

In Microtap’s in-house testing, reproducibility has been plus-or-minus 1.8% for 6061 aluminum at 1,000 rpm. A typical five-run fluid evaluation has 1-2% uncertainty, Mahoney reported. Next, he says the company will work with other laboratories using the same test conditions and materials to verify the standard across labs and machines.

The test has relevance for other metal cutting applications beyond tapping, such as sawing, milling or honing. “We believe that the correlation is good, even for aluminum can D&I [drawing and ironing]. We’ve had good predictability with our results, and the reason for that is at least partially due to the fact that a tapping operation with forming requires fairly high pressure and is a good measure of lubrication,” he said.

Microtap USA has sold more than 50 of its older machines in North America, Europe and Asia and around 20 of the newer LT-120 unit, which made its debut in 2014 and is based on an instrumented tapping machine from Taurox e.K. in Germany.

The company also offers testing services, and about 50 companies that do not own tapping torque units have sent samples for testing, Mahoney said. Some of these companies are sending multiple products on a recurring basis as part of sales or R&D efforts, and others send samples infrequently.

It should be noted that tapping torque units are also available from competitors around the world, including a separate company, Munich-based Microtap GmbH.

Caitlin Jacobs is managing editor of Lubes’n’Greases magazine. Contact her at Caitlin@LubesnGreases.com.