Can Nanotechnology Give Lubesa Competitive Edge?

With a history that includes two Nobel prizes, countless innovative materials and the rapid development of new computer chips, theres been plenty of excitement around nano scale lubes additives. But do they work in practice, and is nanotechnology a winning marketing pitch? TrevorGauntlett looks at the science, its roots and where it can be applied to lubricants.

For at least the past 20 years, cutting-edge nano-scale science has enjoyed the cachet of novelty. Scores of applications are appearing in the lab and on the production line that use tiny tech. But far from being new, the word nanotechnology was first coined in 1974 to describe manufacturing to tolerances of nanometers – thousand-millionths of a meter. Since then, nanotechnology has worked its way into the lexicon of chemistry following the 1985 discovery of the carbon allotrope C60, otherwise known as the Buckminsterfullerene.

This discovery rewrote the textbooks and spawned a new branch of chemistry – the development of fullerenes – which won the 1996 Nobel Prize for Chemistry for Sir Harry Kroto, Robert Curl and Richard Smalley.

As has happened many times in the past, once the Nobel laureates had characterized the simplest material, the other fullerenes, created as byproducts, had much more commercial potential. These byproducts included other Buckyballs (larger spheroids or multi-layered spheroids) and carbon nanotubes, which look like layered scrolls of graphite, about which more will be discussed later.

At the same time, the terms nanotechnology or nanochemistry were applied to the ever-increasing efforts to miniaturize electronic components to make faster computer chips. Nanotech has been a major propellant for the development of quantum computers, and these developments have resulted in techniques to manufacture chemically stable clusters of tens of atoms (metals or simple salts).

====

Quantum computers use subatomic particles ability to exist simultaneously in multiple states, allowing operations to be done faster and using less power than typical computers.

====

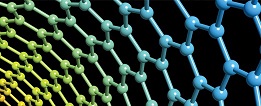

In 2004 came the chance discovery by Andre Geim and Konstantin Novoselov of graphene, the first two-dimensional nanocrystal – the thinnest, lightest and strongest material ever obtained. Roll up a sheet of graphene and join the ends together and you have a carbon nanotube, which brings us back to fullerenes.

====

The full identification of graphene and some of its early applications earned Geim and Novoselov the 2010 Nobel Prize for Physics.

====

Bringing the Nano World to Lubricants

The sub-micron and nano scale of these materials intrigued lubricant formulators. There is a wealth of claims that nano-scale lubricant additives easily flow between the surfaces in a contact, then bind to the surfaces, imparting wear protection or friction reduction. Are these claims valid?

Fullerenes and graphene can be effective solid lubricants and are shown to reduce friction when added to many lubricant and grease formulations. Graphene oxide is another nanomaterial that reduces friction and wear when added directly to a lubricant formulation. Nano-scale tungsten disulphide (WS2) can be manufactured in at least two forms that both claim friction and wear benefits.

Both bulk WS2 and graphite, from which graphene is derived, are solid lubricants and are also added to lubricants and greases to improve friction performance. The additional benefits claimed by taking these materials to the nano scale are that the much smaller particles are more easily carried into the contact and are activated by the rubbing surfaces in a similar manner to chemical additives, such as zinc dialkyldithiophosphate.

Particles of bulk WS2 and graphite can only enter the contact in the hydrodynamic regime, when the surfaces are held further apart by the lubricant than the sum of their roughness. In this regime, the solid lubricants can be thought of as floating into the contact and only coming into action when either there is a sudden and very high load or the sliding speed of the two surfaces drops to near zero. Solid lubricants hold the two surfaces apart under the high load and provide lubrication because of the multiple layers of the solid lubricant sliding against each other

When nano-WS2 or graphene is used, the mode of action appears to change, and the nano-scale versions act like chemical additives that are activated during boundary lubrication, i.e., when surfaces are in contact. The multi-layered spheres or tubes of fullerene-like WS2 are said to roll in the contact during relatively low load and then exfoliate under extreme pressure, depositing a layer of WS2 onto one or both surfaces in the contact. Individual plates of graphene or graphene-like WS2 float freely in the contact until the surfaces come together and grip the plates between them. The graphene or WS2 plate adheres to one surface, reduces friction and restricts damage as the surfaces continue sliding.

Practical Experience

Its been well established that friction reduction leads to better fuel economy or greater torque or both, while wear reduction means greater durability. There is also plenty of solid science to support claims that nano particles can do the same. This is enough for some companies to adopt nano in their marketing, but is it all hype or do nanoparticles work in practice? Martyn Mann, technical director at United Kingdom-based lubricant company Millers Oils Ltd., says a definite yes, they work.

For Millers Oils, nano is not just a branding decision, but a consequence of a genuine and beneficial effect. Nanotechnology enabled us to firstly demonstrate additional benefits to the lubricants by reducing the coefficient of friction and giving measurably better results in dynamometer tests, and secondly to be able to differentiate our capabilities over our competitors, Mann told LubesnGreases.

Did the Big Boys Miss the Nano Boat?

With this practical evidence in the hands of smaller lubes marketers, why did the larger companies appear not to follow suit? Is it because they dont have the data to support such claims? Perhaps, but one probable reason is that lubricants have contained nanoparticles for many years. The calcium carbonate in overbased detergents fits perfectly into the nano scale.

As an employee of one of the global majors, who asked not to be identified, explained to LubesnGreases: We never thought that making claims on nanoparticles would differentiate our products. Therefore, any benefits derived from nanomaterials werent articulated as specifically nano benefits.

Its also the case that the enthusiast consumer market, which likes nano in lubricants in the developed world, is not the target audience for the larger lubricants marketers.

A third reason could also be that the legislative environment in the mid-2000s was not conducive to a regional promotional campaign in Europe based on nanotechnology, as several countries were considering their own actions on nanomaterials. These actions were based on a combination of factors.

One factor is that a desirable property of nanomaterials in the electronics industry is their remarkably different properties from the bulk materials that have the same chemical formulae. Due to their size, therefore, nanomaterials can pass through the skin very easily. Thus, the health authorities in many countries were raising alarms and wanted all nanomaterials classified as new substances.

Sweden banned nano-scale zinc oxide ultraviolet filters in sun block creams, clearly acting because of the particle size. Zinc oxide in other forms is a food additive used to increase zinc intake in humans.

There was tension in the industry when one of the big four additive suppliers published a scientific paper about overbased nano-detergents. Some regulatory specialists working for oil marketers and additive suppliers were concerned that such claims would draw the attention of politicians. The authorities would then be directed to apply new rules to long-established formulations based on nano-scale calcium carbonate, so some regulatory specialists wanted to keep mention of nano away from lubricants.

In addition to the Swedish case, France and Norway proposed that nano particles be subjected to additional reporting requirements beyond those of REACH. For any international company, the prospect of each EU member state being allowed to make its own rules on reporting or restrictions is a potential nightmare.

Legislation is still under development. The Organization for Economic Cooperation and Development set up its Working Party on Manufactured Nanomaterials in 2006, and it is still active, having produced more than 80 reports by the end of 2017. Also in 2017, there were at least three conferences in Europe focusing on legislation for nanomaterials. Two were based around the European Unions NanoMONITOR program, which gathers data on the risks of nanomaterials.

In such a rapidly developing health, safety and environmental landscape, where lubricants are not even on the radar of the lobbying bodies, many of the larger lubes marketers will want to stay clear.

Snake Oil?

The explicit use of the word nano to explain the benefit of some lubes is a claim mainly confined to enthusiasts mostly located in North America. This doesnt mean that the additive or chemical company trying to sell you nano-particles as a friction modifier or antiwear additive is a snake oil salesman. Nor does it mean that your competitors claims are fallacious.

If your target market isnt niches such as motor racing, market precedent appears to say that claiming the benefits of nanotechnology doesnt win you customers. Plus, the rapidly developing legislative environment, particularly in the EU, could mean that nano claims will draw an administrative burden in the future. However, balance that against the absence of nano marketing claims from the major players, and it just could be a worthwhile avenue to walk down.