The market for data center immersion cooling fluids is projected to grow about tenfold through 2032, Kline & Co. predicted recently, spurred by findings that operational improvements can more than cover the cost of large data centers switching from air to immersion cooling.

Demand for such fluids is currently very small but should exceed 250,000 metric tons by 2032, Pooja Sharma, a project manager in Kline & Co.’s Energy Practice, said during an online webinar on April 19. Most of that growth is expected to occur after 2027, she said, when server manufacturers recommend immersion coolant specifications for servers.

There is a pressing and growing need for improving cooling systems for data centers, Sharma said.

“The thermal impact of data centers is not just confined to power consumption,” she said. “It also impacts overall water consumption. Water is consumed in data centers to just keep them cooled.” She added that water consumption is greater when systems use artificial intelligence because their data density is quite high.

Sharma said several factors should encourage data centers to employ immersion cooling. It lowers total cost of ownership, enables central processing units and graphic processing units to perform at high levels and allows centers to reduce their energy footprint.

Use of the immersion cooling is currently constrained by risk and uncertainty, insufficient data about performance of immersion systems, cost and the inertia against switching from legacy air-cooling systems. “The biggest challenge for data center operations is in shifting an entire facility from air-cooled to immersion cooling,” she said. That is because the existing cooling infrastructure is going to be depreciated much faster than planned, which has a negative effect on the return on investment of the new liquid cooling installation, she said. “That is one point of resistance when it comes to moving to this new technology.”

There are two categories of immersion cooling fluids – synthetic and biobased. Synthetics include gas-to-liquid hydrocarbons, hydrofluorocarbons, polyalphaolefins and esters. Among the companies supplying such products are Shell and BP’s Castrol. Suppliers of biobased fluids include TotalEnergies and Cargill. 3M was once an important supplier of hydrofluorocarbon immersion coolants, but the company recently announced its exit from the business.

The rest of the data immersion cooling value chain includes cooling specialists, server manufacturers, data center operators and integrators, and end users. Cooling specialists includes companies that supply, install or service modular immersion systems. Server manufacturers make the server sets and chips. Data center operators and integrators include big data center operators, data center operators with immersion cooling technologies, and information technology infrastructure providers and server manufacturers. There are several segments of end users, including hyperscale, enterprise, high-performance computing, edge and 5G telecommunications, and colocators, which rent rack space for third parties.

According to Kline’s study, there are 7,000 data centers spread across the world, with the United States accounting for the largest share, of about 40%. “Density is highest in the United States., followed by Germany, the United Kingdom and China,” Sharma said.

She noted that there is growing interest around the world to reduce consumption of power and water It is estimated that between a third and half of power consumed by data centers is for air cooling and extracting systems. “Therefore, data centers are under increasing pressure to reduce their overall power consumption, especially with more than 80% of the global electricity still being generated from fossil fuels,” Sharma said.

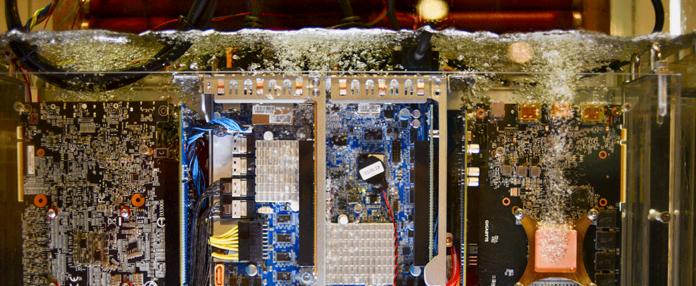

Immersion systems dielectrically cool all parts of data processors, she said, including motherboards, chipsets and wires. “This is becoming more important in places where temperatures are much higher than the global average,” she said.

Kline identified four key elements to cooling systems: the rack mount or hardware; the software; the fluid; and the cooling method. The rack mount is where computer power is placed. In the case of immersion cooling, the housing of the tank also contains the carrier for the fluid. The software remotely maintains or manages the rack, the tank and the fluid. It also gathers information about operating conditions. The software also is the major heat source.

The fluid is the most critical part of the solution, Sharma said, as it is used to extract heat from the system. It has its origin in heat transfer fluids and engineering fluids used in the industry, but formulators are now developing products for unique software applications. In addition to the ability to manage heat, fluids need to be compatible with the materials they contact.

Sharma said the two main immersion cooling technologies are single-phase, typically using hydrocarbons, and two-phase, which uses fluorocarbon-based fluids. Single phase designs are popular because they cost less, but two-phase designs are preferred for extreme rack densities – data center density is calculated by the number of kilowatts consumed per cabinet – with some providers claiming to support 250 kilowatts in a single rack. Sharma pointed out that a few single-phase immersion cooling vendors also claim to support up to 200 KW. Most mainstream applications for immersion cooling range from 15 to 50 KW per rack.

The study is titled, “Immersion Cooling in Data Centers: An Emerging Opportunity.”