Sludge and varnish in turbines, such as those used for power generation, have been observed more frequently in recent years due to increased use of API Group II and Group III base stocks in modern turbine oils. Contrary to previous published research, a study conducted at BASF points to aminic antioxidants as a key part of the solution to this costly problem.

Group II and Group III oils show better thermal stability than Group I base stocks. On the other hand, they exhibit poorer solvency for high molecular weight byproducts of oil degradation, which trigger sludge and varnish formation. There is not one type of varnish. For example, it could look yellowish, brownish or black and be soft or rather hard. More than 80 different varnish chemistries have been identified over the years.

Varnish-related failures can lead to unscheduled downtime with costs of up to $1 million for a single unit. Varnish in the turbine bearing can result in a much smaller clearance, increasing the oil film temperature and pressure. The loading capacity of the bearing is also decreased, which reduces the safety and reliability of bearing operation. Since varnish typically is a sticky residue, it may cause valve malfunction, blocked flow lines and premature filter blockage. Other effects of varnishing include decreased efficiency in the heat exchanger and seal malfunction, which could result in leaks or increased friction of the dynamic seals.

The process of varnish formation begins with polymerization of soluble oxidation products, forming oligomers. As the oil reaches the saturation point—when it is unable to hold any more of these oligomers in solution—so-called soft contaminants will drop out of solution and form insoluble particles of a median size around 80 nanometers. Since these particles are polar, they clump together in the environment of a non-polar mineral oil.

The polar particles are attracted by metal surfaces inside the turbine, forming sludge. This process is reversible for organic deposits, as it is possible to re-absorb them back into the oil, for example by using polar co-solvents like esters.

However, inorganic deposits formed by chemistries such as zinc dialkyldithiophosphate cannot be re-dissolved into the oil.

Air plays a very important role in sludge formation. It contributes to varnishing both by a physical route, such as heat generated by the implosion of entrained air bubbles under pressure, and by a chemical effect, such as chemical oxidation. The resulting lubricant degradation leads to viscosity changes, corrosion and the formation of sludge and varnish.

Oxidative aging is the dominant process that influences lubricant life. Since air contributes to aging through physical effects, it can be concluded that excellent air release performance is important to prevent varnishing. Sulfur compounds, which can be found in turbine oil additives, increase sludge and varnish formation and could catalyze further oil oxidation. They can also react with water and produce corrosive sulfuric acid.

Water vapor may also be involved in these processes. It is known that water can increase the number of metallic wear particles, which for their part could contribute to lubricant aging.

The author found more than 20 different chemistries in a sludge sample using gas chromatography mass spectroscopy. The functional groups in these molecules include carbonic acids, lactones and ketones.

The author also carried out an X-ray diffraction analysis of sludge samples, finding iron oxide-based crystalline matter, which could be abrasive and function as a catalyst for partial oxidation in the bearing.

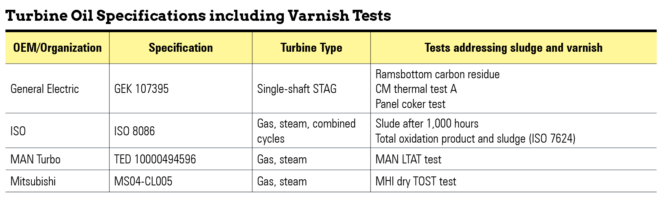

According to the most important national, international and original equipment manufacturer standards, turbine oils must fulfil many different technical requirements. However, it is remarkable that not all the standards address the issue of varnishing. Specifications that include varnish tests include the international ISO 8086 standard and the original equipment manufacturer standards MAN Turbo TED 10000494596 and Mitsubishi MS04-CL005.

In principle, there are several different strategies to reduce varnishing and deposit formation:

- Using more-polar base stocks, like polyalkylene glycol, that have similar stability but better solvency for sludge than hydrotreated base stocks. PAGs typically are more polar than Group II and Group III base stocks in the Turbine Oil Oxidation Stability Test. In a study published by Govind Khemchandani of Dow Chemical Co. in Lubrication Science journal, the use of PAG as a base stock resulted in a clean glass tube, whereas a polyalphaolefin based turbine lubricant showed severe deposit formation with the same additive package.

- Adding a cosolvent to the lubricant at up to a 10% treat rate in order to improve the solvency for sludge. In the severe Mitsubishi Heavy Industries Dry TOST method, comparing a Group II base stock containing a turbine oil additive package at 0.43% treat rate with the same formulation containing cosolvent on top, the passing level of sludge can only be achieved by the second formulation. The cosolvent formulation also shows a filter residue with brighter color than the formulation without cosolvent.

- Reformulation of the antioxidant package might help, as some aminic antioxidants are suspected to form deposits. This can either be done by replacing aminic antioxidants with another type or by using formulations with aminic oxidants that have less tendency toward sludge formation.

There seems to be a broad consensus that Group I base oils show better sludge and varnishing behavior due to polar components that result in better solvency.

The literature also indicates that aminic antioxidants are less depleted when hindered phenolic antioxidants are present, which regenerate the aminic antioxidants and prevent them from forming varnish. However, the author would challenge this thesis, supported by work from researchers at Mitsubishi Heavy Industries and Kyushu University in Japan, published in Tribology Transactions in 2004.

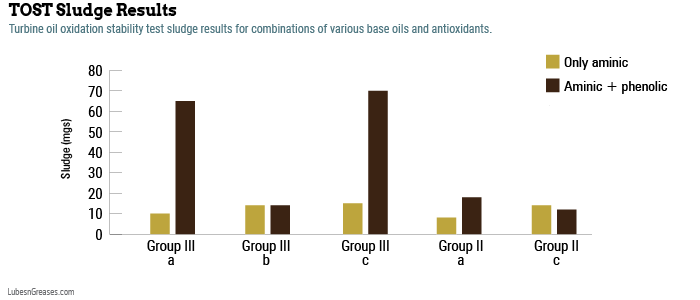

The researchers carried out a comprehensive study comparing many different turbine oil formulations based on Group I, II and III base stocks and different antioxidant technologies—only phenolic, only aminic, aminic plus phenolic, and ZnDTP as a secondary antioxidant. They found that the best turbine oil technologies in terms of lifetime and sludge are based upon Group II and III base stocks with aminic antioxidants only, which is in contradiction to most of the literature.

These results have been confirmed in this author’s lab, where different Group II and Group III base stocks were compared using a turbine oil formulation with only aminic antioxidants and another formulation with aminic and phenolic antioxidants. Overall, the sludge generation for the formulation with only aminic antioxidants was no higher—and in two cases significantly lower—than the formulation containing a combination of phenolic and aminic antioxidants. These results are in contradiction to the classical thesis in literature that aminic antioxidants alone show sludge and deposits, rather than their combination with phenolic antioxidants.

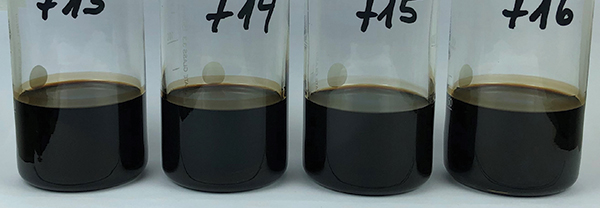

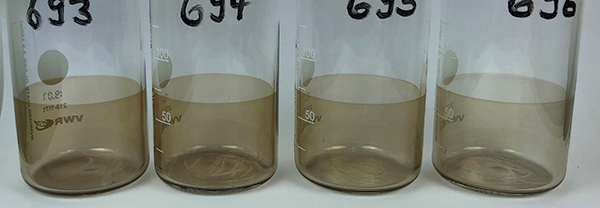

These findings can be confirmed using the severe MAN Diesel & Turbo Lubricant Temperature Aging Test. When using a combination of phenolic and aminic antioxidants, a significant amount of black varnish on the test beaker and filter can be observed, whereas the formulation with only aminic antioxidants shows a bright filter and a clear beaker.

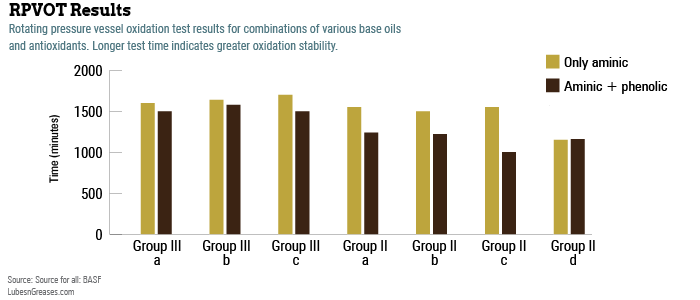

In order to check whether the oils with only aminic oxidants show a longer lifetime in addition to a lower tendency to form sludge, RPVOT and TOST lifetime measurements were carried out. The TOST lifetime of a classical turbine oil formulation with aminic and phenolic antioxidants in a Group II base stock is around 15,000 hours, whereas the formulations with only aminic antioxidants are longer. The RPVOT values also are consistently higher for the formulations with only aminic antioxidants.

All of these results confirm that long-life turbine oils with a low tendency toward sludge formation consist of Group II and III base stocks and only aminic antioxidants. Against the background of an increased use of Group II and Group III base oils in turbine oil formulations, these findings indicate that in the future, the formulations should be revised to explore the full benefit of Group II and III base oils.

Thomas Ruehle, Ph.D., is technical service manager for lubricant components with BASF SE, where he is responsible for lubricant additive components and base stocks in Europe, the Middle East and Africa. He has 24 years of experience in lubricants and related chemical industries. Contact him at thomas.ruehle@basf.com.